I bought 3 new bearings and 2 new seals for the swing arm main pivot. Cost NZ$62.77

I fitted them to the swing arm and assembled the swing arm back into the frame this evening.

One thing I didn't cotton on to during dis-assembly of the swing arm is that the main bolt/axle that goes through the main swing arm pivot can effectively be used as a 16mm Allen head key for doing up the threaded spacer.

When I was about to tighten the spacer up between the swing arm and the frame, I made sure to first do up the upper rear frame bolt as shown circled in red below. This just stops the frame from getting pushed apart as the threaded swingarm spacer is tightened up. Probably a bit of a small point as the frame probably wouldn't spread too easy anyway.

I bought a swing arm chain slider off Adrenalyne Motorcycle wreckers in Mt. Maunganui for $25. The rubber was developing a few cracks especially in the stressed part of the loop that hooks over a lug on the top of the swing arm. I just squished a bit of 5 minute Araldite into the cracks and left it for 24 hours. It seems to have done a pretty good job.

The threaded rivet thing on the side of the swing arm (that the bolt with a slotted and stepped washer goes into to hold the chain slider rubber onto the side of the swing arm) would spin when I tried to undo the bolt so that I could fit the chain slider. By squeezing in behind the stepped slotted washer with a pair of side cutters I was able to get the screw out. This will be a problem if I ever go to take the chain slider off again, but hopefully that is not something that I will be doing.

Also, I pulled apart the little double swivel spacer item that goes on the LH side of the swing arm and has the main swing arm pivot bolt go through it. I was little surprised to find 2 O-rings in this little sub-assembly. But I just gave it all a good clean and greased it up before re-assembly. The bushes are noticeably worn, but hopefully it will be OK for another 30,000 kms.

Note that on the body of this part is an arrow with an "F" stamped next to it. Obviously, this is so you don't forget how to orient the part upon re-assembly.

At the moment, I have to confess that I don't actually know what this swivel spacer part is for. But I will know soon enough.

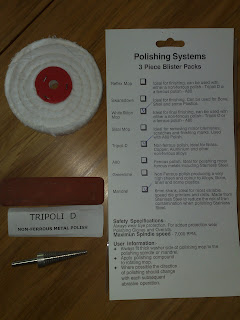

Next up is the rear shock. The polishing of the front forks is not quite right, so I am taking a bit longer to get the front end sorted than I had hoped.